Tube

Drawing

In this blog we will learn about Tube drawing process

What is Tube drawing process ?

It is a process in which a larger hollow cylinder or tube or

pipe diameter is shrink into smaller

diameter of hollow cylinder /pipe/tube by drawing through a die.This process is

often done after hot working of tubes so that we can get good surface finish

and other benefits

What are the types of tube drawing ?

Tube

sinking : In this process a tube is simply draw through a

die to reduce its outside diameter and inside diameter. As you can see there is no internal support is provide

inside so the surface finish produce inside the pipe/tubes are uneven due to

that surface thickness increase.

Fixed

Plug : In this process a mandrel is provide inside the tube. In

this the mandrel(plug) is fixed at its position . this provide better surface

finish in inside diameter.This process is use limited because long tubes can’t

be drawn and area reductions are limited in this kind of process.

Floating

Plug/Mandrel : In this

process a floating mandrel/plug is used .In this case the position of

the plug/mandrel is controlled by the tangential and normal forces of the

tubes/pipes of the material.The friction force in floating plug/mandrel is more

than the Fixed Plug.

Moving

Mandrel : In this process both the tube and mandrel are

move together from the die.It produce high quality tubing with very good dimensional accuracy.

What are the advantages of tube drawing process?

1.High surface finish

2.Good mechanical properties of tube due to the strain

hardening effect

3.Can produce thin and smaller diameter tubes

4.Good dimension tolerance

5.Irregular tubes shapes can be produced by this method

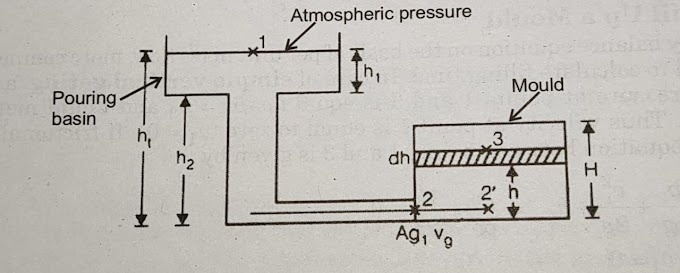

Formula used for Drawing process

σd = Yield Strength of the material

B = µcot(α)

µ =

co-efficient of friction

α = half die angle

R1 = radius of tube at the exit of the die

Ro = radius of tube at the entrty of the die

What are the factors the effects tube drawing process ?

- Coefficient of friction

Strength of job material

Temperature of job in which tube drawing process is occurring

Die angle

Speed of drawing

Reduction area (ratio)

1 Comments

I have query , pl. Send contact no.

ReplyDeleteif you are not getting it then ask i am glad to help