Difference between different types impeller (Open, Semi-Open , Close)

Open Impeller:

Those impellers vanes which are open on both sides and have no wall surrounding the vanes.

Application: Used as a pump where workload is low and fluid contains abrasive particles.Note: these impellers less prone to clog or particle blockage

Advantage :

- Easy to clean

- Easy to repair

- Faster

- Can handle suspended Solids

Disadvantage:

- Only good for smaller load work

- Low efficiency

- Required high NPSH(net positive suction head) to reduce cavitation effect

Semi-Open Impeller:

Those impellers vanes which are open on both sides and have wall surrounding the vanes.

Application: Use for the medium workload. It can also handle mud or abrasive particle in the fluid. This impeller efficiency is in between close and open impeller

Advantage :

- Used with fluid have dirt abrasive particle

- Higher-strength as compare to open impeller

- Better efficiency as compare to open impeller

Disadvantage:

- Clearance between the vanes and casing must be small else large slippage and recirculation will occur

- Low efficiency as compare to close impeller

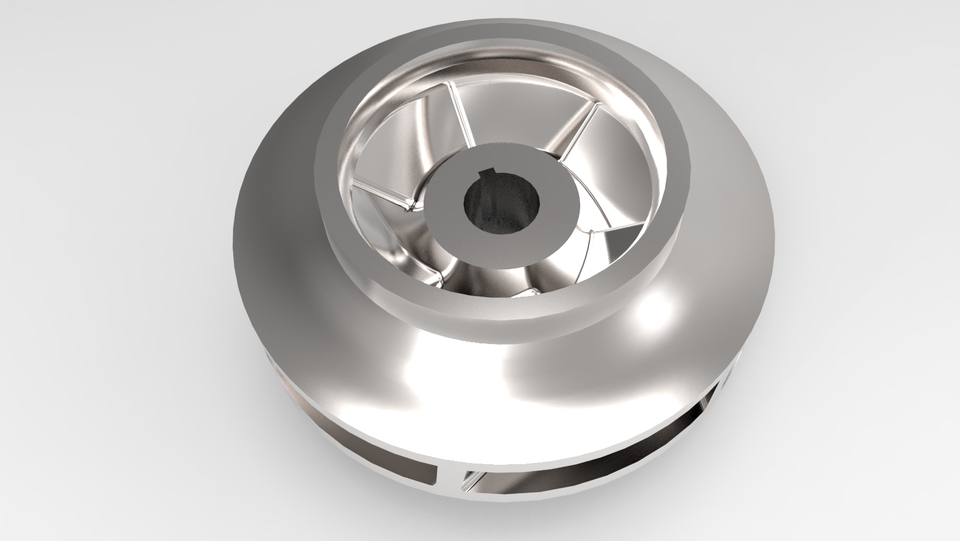

Close Impeller:

These impeller vanes have have a wall on both sides (front and back) .It increase its strength

Application: These impellers are used for heavy workload and Commonly used with clean liquid (water treatment plant or other industry dealing with liquid )

Advantage:

- High efficiency as compare to open and semi open impeller

- Provide more flow at low NPSH(Net positive suction head)

- Give constant efficiency during work

Disadvantage:

- Complex Design

- Expensive (high maintenance and making cost)

- More Prone to clogging

- Not suitable for abrasive fluids

0 Comments

if you are not getting it then ask i am glad to help